Alone strong, together stronger.

Together with proven partners, Kübler works out solutions for the solar industry.

Its specialisation in core industries allowed Kübler to gain a deep insight in the structures and needs of very different market segments and, thanks to the Kübler “Design for Manufacturing” approach, to develop continuously its customer-oriented consultancy and service expertise. Especially for one of its core branches, the solar industry, the Company is networking closely with partners from neighbouring branches such as the drives and automation technology. In association, they create innovative solutions, tailor-made for this globally emerging sector. These are a substantial part of the whole value chain. The customers do not only benefit from products perfectly suited for their needs, but also from a wide supplier base. These suppliers are experienced development partners, used to work reliably together hand in hand. This cooperation results in extra possibilities and cost-efficiency. These possibilities reach from special customer interfaces, particularly quickly manufactured and economic complete drives, up to the further development of highly accurate, robust measuring and assembly processes, including the proven and tested implementation on site.

The Solar team is growing

For several years, Kübler’s Solar core branch team has been continuously growing. This industry is experiencing a phase of huge changes. The path away from fossil and nuclear towards renewable energy sources is currently one of the most significant and ambitious topics of our time – as well in

Kübler has accompanied the global growth sector Solar energy since the beginning with its weather proof products, specially adapted for harsh outside uses, and has acquired, besides comprehensive knowledge about the specific needs of the branch, extensive project experience. The Black Forest Company sees a great deal of development potential especially in the system and drive technology for the sector of the so-called industrial plants, power plants and local heating systems.

CSP- A key technology within solar heat

CSP – Concentrated Solar Power – is the name of a key technology in the area of alternative energy production that still bears a particular potential of enthusiasm for researchers and developers: the energy of the sun is concentrated with mirrors to heat water. The generated steam drives a turbine. And, since large quantities of heat are relatively easy and simple to store compared to electricity, these solar power plants generate current even when the sun is not shining. CSP plants exploit their full potential in the sunniest regions of the world. The energy yield of photovoltaic plants installed in these regions is reduced, already because of the heat. Moreover, the thermal power plants circumvent a part of the “electricity network problem” since, especially in hot regions, these networks are missing for a targeted distribution of a central current production up to every last corner. CSP power plants simply need water for the operation of the steam turbine and electricity lines designed to bring the energy to the places where it is required.

In CSP plants, mirrors tracking the sun concentrate the light on an absorber. This absorber generates superheated steam that drives a turbine connected with an electricity generator. Kübler supplies these plants with position sensors adapted to various technologies: in tower plants with heliostats, individually controlled mirrors concentrate the sunlight on a tower in which an absorber is installed. The parabolic trough system consists in long curved mirror rows, which bundle the sunlight on a receiver pipe filled with steam or with another medium. A third technology is based on direct evaporation of water: while parabolic trough mirrors track the sun with the help of powerful hydraulics, so-called Fresnel collectors allow, thanks to their light construction, a very cost-effective exploitation on sites where large surfaces are available. Several parallel flat mirrors arranged at ground level reflect the sunlight on a receiver pipe. To that purpose, they track the vertical course of the sun with the help of many drives.

Sensors with Solar competence

Kübler components and solutions for the solar branch comply on the one hand with the required cost-efficiency and longevity of components designed for heavy-duty operation in hot regions. In addition, they are outstanding for their perfect system integration. A combination that ensures advantages for the customer. Regardless of the CSP technology used: solar thermal power plants must ensure an optimal efficiency all along their value chain, in order to be able to supply energy while covering their costs. An efficiency that does not stop with the acquisition costs, but that also takes into account the maintenance costs over a long service life. Extreme weather conditions, which the components must resist reliably all along their long service life, belong therefore to the basic requirements. The robust Safety-Lock Design, the shock and vibration resistance and the high IP protection level predestine the incremental and absolute encoders for heliostats with position detection on the azimuth and height axes. Kübler inclinometers of the IS series, with their compact and sturdy plastic housing are the ideal products when a high IP protection level and a particular temperature resistance are required. Both are important for use in parabolic trough systems, but also in photovoltaic plants. Contactless, magnetic measuring systems such as the Kübler Limes LI50 are particularly suited for parabolic trough plants with axis control. In their die-cast housing, these linear measuring devices offer maximum IP protection, require little mounting space and are shock and vibration-resistant.

Solutions thanks to cooperation

A 250 Megawatt Fresnel plant is being built in Rajasthan, in

The structure of a Fresnel collector is very simple: a steel frame carries flat primary reflectors that are arranged in a row behind each other. The receiver is positioned at a height of some metres above the primary reflectors and consists mainly in secondary reflectors and an absorber pipe. In an average-sized plant, the reflector height is about ten metres; the gigantic plant supplied by Kübler jointly with his partner Framo-Morat requires a distance between the reflectors and the absorber reaching 50 metres. This is why the position of the reflectors must be determined with an accuracy smaller than 0.01 degree to meet the requirements of this ambitious plant design.

While Kübler’s partner, the Black Forest Company Framo-Morat, manufactured the drive, the sensors manufacturer supplied the tailor-made and nevertheless low-price measuring system and supported its cost-effective integration in the drive.

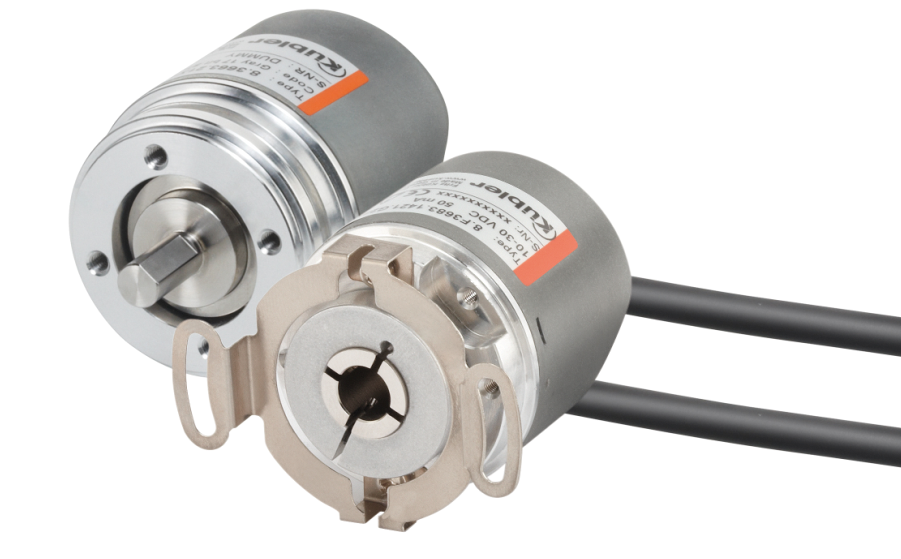

Within the framework of this cooperation, the Kübler solution consisted in the further development of the high-accuracy Kübler absolute encoder Sendix F36. The result is a product that is ideally suited for this task. To achieve this goal, the already high accuracy of the encoder was doubled, and several solutions were worked out in cooperation with Framo-Morat all along the value chain: from the improvement of the measuring and assembly processes and a common failure analysis on site, up to the optimisation of the logistics between the partners. In short: a cost-effective global solution made of product, assembly, system, testing and logistics, with unexpected advantages in the realisation, which was received enthusiastically by the customer. His competitiveness was strengthened and the time to market shortened. For Kübler, this successful cooperation project became the basis for further development steps in this demanding sector. And for many solutions offered by the Company also in other sectors.

Photos:

|

Solarfeld_PE.jpg

Picture subtitle: Integrated drive solutions for Fresnel plants

|

|

F36XX_.jpg

Picture subtitle: Compact electronic encoder for all drive technology applications

|

|

z1853_Limes_LI50_B2. jpg

Picture subtitle: Limes with high IP protection level for applications in parabolic trough systems

|

PS: The content is provided by Kübler

Contact:

Filippo Zerbo, Team Manager

Marketing Communication

filippo.zerbo@kuebler.com

Phone: +49 7720 – 3903-80